I started to design and create with the aid of a 3D CAD model, the mechanical assembly for 26 WIFI and CAN BUS controlled lighting nodes to be fitted around the dome. Following collaboration with electronics engineer we designed the PCB and power system.

I created 3D printed fixing brackets with steel threaded inserts that fix the PCB to the dome. Using laser cut acrylic I designed a clear cover to protect the PCB and by etching the acrylic to create a LED diffuser as a single piece.

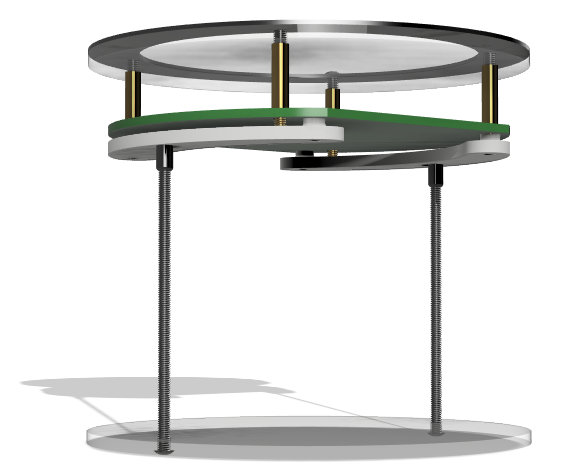

The metal rings are capacitive touch sensor conductors and provide no mechanical purpose. Currently they are uncoated mild steel, chosen as a low cost initial batch. For safety and aesthetics the oxadisation (rust) will need to be reviewed and an alternative low cost material or coating needs to be considered.

PCBs are designed in-house at Surrey and Hampshire Makerspace for the project. All boards were SMD soldered in our workshop before programming with custom software.